Ross Vandermark, national product manager with VELUX, worked on the team that developed the new VELUX Dynamic Dome Commercial Skylight. Here are a few insights into how they approached innovations to existing acrylic bubble commercial skylights.

Q: What’s missing from acrylic bubble skylights used on commercial buildings?

A: We reviewed existing designs – including our own – on the market and looked for ways to improve their performance from a daylighting, weather protection and ease of installation point of view. What we found was that many existing designs aren’t able to capture sunlight when the sun is low in the sky early in the morning or late into the evening. That’s very important for warehouse managers looking to reduce their use of electrical lighting, so we went after a better light harvesting design first and came up with the Dynamic Dome.

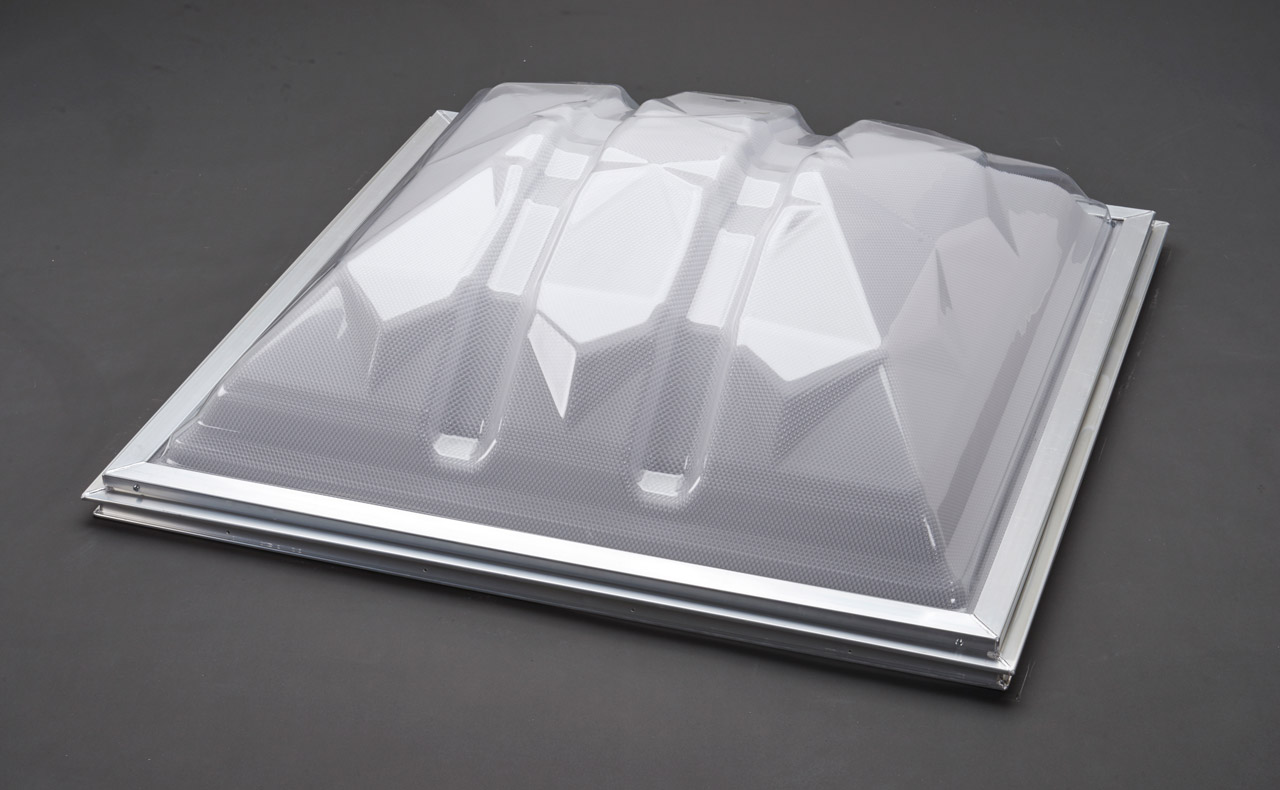

Q: How is the design different from a bubble shaped skylight?

A: Our goal was to make a dome shape that would capture more sunlight and be both distinctive and aesthetically pleasing. The dome walls are engineered to reflect less and harvest more light when the sun is low in the sky. This means that warehouses that use the VELUX Dynamic Dome commercial skylight can turn off their lights 56 minutes sooner in the morning and leave them off an additional 47 minutes in the evening. That adds up to 626 hours of lighting savings per year.

One of the issues with existing bubble skylights is they are easily damaged by hail. We created a ridges and ribs that create structural strength and a distinctive architectural appearance.

Q. What was your approach to the frame design?

A. Performance was our No. 1 priority in designing the frame. Existing acrylic bubble skylights expand and contract, which can contribute to cracking, and often have condensation issues. The Dynamic Dome design has a one-piece encapsulating thermoplastic inner frame with similar expansion/contraction as the inner dome to reduce cracking. The frame is also 100 percent thermally broken to eliminate frame condensation. Finally, our one-piece inner frame moves water to corner cut-outs where wicking tape removes it to the roof.